Have you ever thought about all the parts that go into a car’s steering and suspension systems? It’s thanks in part to control arms, bushings, and ball joints. Let’s review them and how they affect your vehicle’s performance.

The Purpose of Control Arms, Bushings, & Ball Joints

Control Arms

Control arms keep your front wheels connected to your car. Most vehicles have an upper control arm for the uppermost area of the front wheel and a lower control arm for the lowermost area of the front wheel. Vehicles with a strut-style suspension only have a lower control arm. Each arm is connected to the vehicle frame by two arm bushings.

The design of a control arm will vary based on the vehicle’s suspension, but they’re typically A-shaped, L-shaped, or wishbone-shaped. Control arms are located at the front axle at each of the two front wheels. Each control arm has connection points at either end to link a wheel’s steering knuckle to the frame of the car.

Causes & Signs of Damage

Control arms are typically made of stamped steel, cast iron, or cast aluminum. They’re designed to handle a lot of impact but are still at risk of wearing out.

Common causes of control arm damage include:

- driving over uneven surfaces

- rust, extreme flexing, or breakage on the frame

- worn bushings

- worn or cracked ball joints

A damaged or misaligned control arm may cause the following symptoms:

- vibration in the vehicle

- drifting steering wheel

- wobbly wheels

- grinding noises

- inconsistent braking

- uneven tire tread wear

Do a visual inspection for any cracks or excessive wear on your control arm if you notice any of these issues. A mechanic will know whether it needs to be replaced or just realigned.

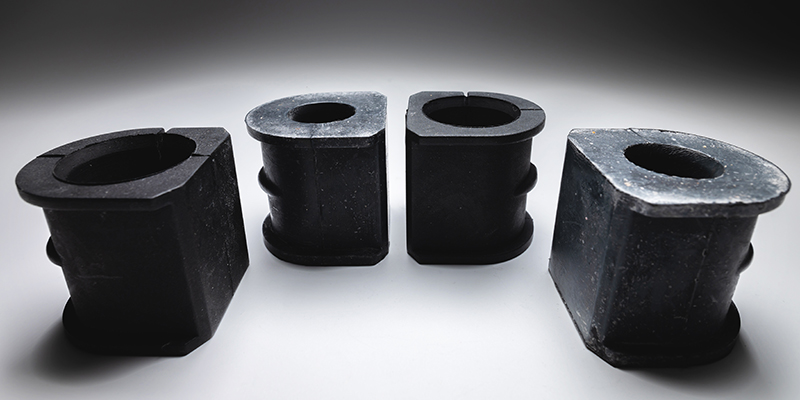

Bushings

Bushings connect control arms to your vehicle’s frame. They’re often made from rubber or polyurethane and are mounted on the steering joints and vehicle suspension to help control the movement in the joints, absorb road bumps, and reduce vibrations and noise. By preventing friction from metal-on-metal contact, the bushings protect the metal joints from damage.

Causes & Signs of Damage

Aside from age, bushings may be damaged by:

- dirt, salt, and other debris buildup

- too much friction or heat

- carrying heavy loads

Signs your bushings are wearing down include:

- loose feeling in the steering wheel

- vibrations when braking

- clunking noises during acceleration or braking

- excessive tire wear

A worn bushing can pose a serious hazard for you and other drivers. It can also put stress on the vehicle’s joints and damage the vehicle if/when its components snap. Look for any cracks or tears in the bushing if you notice these signs. When in doubt, leave the inspection to a professional.

Ball Joints

A suspension ball joint is a small, cylindrical piece of metal that connects the steering knuckle to the lower control arm. Your car’s suspension moves up and down as you drive, but the ball joint always keeps the tires at the right angle. It also allows your car’s suspension system to move freely and absorb shock from the road. This reduces wear on the suspension system, creating a smoother ride.

Most vehicles have both an upper and lower ball joint, but those with a strut-style suspension will only have a lower ball joint. Ball joints are made of steel, enclosed in a casing, and are filled with grease to prevent wear.

Causes & Signs of Damage

Ball joints experience general wear and tear over their lifetime. This wear creates more space between the stud and socket. If a stud becomes too loose, your safety can be at risk. In the worst case, a wheel can become partially detached from your car.

Several things can create issues for ball joints:

- stuck dirt, grime, or other debris

- not enough lubrication

- rust or corrosion buildup

- excessive use and friction

Common signs of a worn ball joint are:

- rattling or shaking feeling in the suspension or steering wheel

- knocking, clunking, or banging sounds when going over bumps or making turns

- uneven tire wear

- vehicle drifting to one side

If you notice any of these signs, follow these steps to assess the ball joint. You’ll be looking mainly for any cracks or rust and checking if the ball joint moves more than one inch in either direction. Have an expert replace your ball joint if you notice any of these issues.

Suspension Maintenance

All these parts are essential to the longevity of your car’s suspension system. If one fails, it can have a significant impact on how your car performs. You can extend the life of these suspension parts by driving with care (i.e., avoiding potholes) and inspecting them roughly every 80,000 km.

To make sure everything’s in the right position, some control arms come with adjustable attachment points on the frame. A professional mechanic can make this adjustment for you to keep the parts aligned so your vehicle drives straight.

You can have all these parts inspected, diagnosed, and serviced/repaired at any NAPA AUTOPRO service centre.

For DIY repairs, browse the wide selection of steering and suspension products available on NAPACanada.com. Any time you work on your vehicle, remember to wear protective equipment, like gloves.

If you have any questions about control arms, bushings, ball joints, or anything else to do with your suspension system, visit a NAPA Auto Parts store to speak with an expert.